Инновационные технологии

в нефтегазовой промышленности

в нефтегазовой промышленности

Инновационные технологии

в нефтегазовой промышленности

Инновационные технологии

в нефтегазовой промышленности

About Us

SGK Region Ltd. (OOO) is a fast growing company established in 2008.

Our main activities include the development of high energy systems for oil recovery improvement and manufacture of high technology products. We service oil and gas producers by offering integrated services aimed at increasing oil and gas recovery of productive formations. We provide engineering, research engineering and development of advanced technologies. For over 3 years SGK Region has been applying its advanced Acoustic Powder Pressure Generator (APPG) at various oil and gas fields developed by major Russian oil companies such as Rosneft (its subsidiary OJSC Samaraneftegaz), Lukoil and TNK-BP (its subsidiary OJSC Orenburgneft). Our technology of APPG application has a successful track record of enhancing oil recovery. SGK Region proudly employs highly skilled scientific and engineering staff thereby ensuring high level of services rendered to our clients.

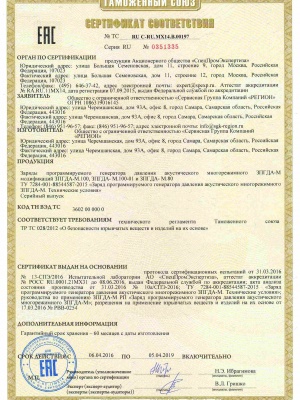

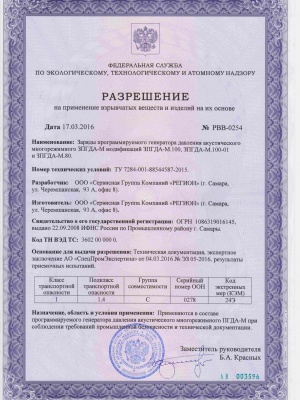

Technology

Our Acoustic Powder Pressure Generator (APPG) (Technical Specifications No. 728419407507802 2003, License No. RRS 049387 dated 06.08.03 issued by Gosgortekhnadzor of Russia (Federal Mining and Industrial Supervisory Authority)) is primarily designed to stimulate oil production from well bore zones that are colmataged during operation with paraffin-based,- asphalt and bituminous,- and slurry sedimentation.

APPG consists of pulsating charges with the corresponding equipment, a wire line connected with a geophysical cable, a tray underneath, sleeves between charges and charges on edges of the generator. The generator is placed opposite to formation, so that the charges in a fluid-filled well, when exploded, apply a thermal and gas chemical, as well as high frequency vibrowave treatment of the producing layer.

Here is the essence of the vibrowave technology using APPG. After the generator is let down, it is installed opposite the producing formation. After which current is fed via the cable using glow plugs mounted into a propellant of end walls of the daisy. After their ignition all other elements continue burning thereby increasing pressure and temperature in the well. After explosion each charge gains its own vibration mode which occurs under certain conditions which resonate with the fluid-filled charge cavity. Pressure waves are generated; they are synchronous with the entire device. Then these waves are induced in PTA through the casing string. Frequency of the waves reaches 20 KHz with ranges of up to 5-10 MPa. The formation pressure mounts dramatically. Simultaneously, the waves penetrate PTA which precipitates secondary acoustic emission with the corresponding vibrations. Productive formation is impacted with high temperature vibration waves; this enhances the thermal-gas-chemical formation treatment effect. The formation gets fractured, its perforation tunnels grow wider, and thus filtration- and other properties of the headers are modified. Ultimately, the formation is fractured, while vibration in the formation reduces maximum pressure of the fracture on rocks.

SGK Region in association with OJSC ROSNANO is currently working on developing high powered downhole devices (APPG-N, PK-N (the so-called perfogen), jet charges featuring high penetrative power) using aluminum nanopowder as solid fuel (V-Alex (100)). This project is currently undergoing scientific and technical evaluation.

Services

Acoustic Powder Pressure Generator (APPG) (Technical Specifications No. 728419407507802 2003, License No. RRS 049387 dated 06.08.03 issued by Gosgortekhnadzor of Russia (Federal Mining and Industrial Supervisory Authority)) is primarily designed to stimulate oil production from well bore zones that are colmataged during operation with paraffin-based,- asphalt and bituminous,- and slurry sedimentation.

The advanced oil recovery method using ‘pulsating’ charges – the new generation of generators that in addition to thermal-gas-chemical formation treatment generate intense vibrations at PTAs at various frequencies – is a relatively new phenomenon. Acoustic Powder Pressure Generator (APPG) is the first device with ‘pulsating’ charges that has been proven and implemented. The generator developed by SGK Region consists of several (up to 10) channel solid-propellant charges. The charges feature equal sizes and simple design. The gauge is 112 mm - 114 mm, the length is up to 12 meters, and the maximum weight of the charge is 120 kg. Operating temperatures are up to +90 Celsius; depths are up to 5 km.

Partners

SGK Region entered into contracts and partnerships with leading Russian companies and R&D centers, oil and gas equipment and material developers and manufacturers, as well as Russian defense enterprises, developers of fuel compositions, and ammunition proving grounds. Our partners include Perm Powder Mill, GRUP PM R&D Center, Privolzhsky State Ammunition Proving Ground, Department of Solid Chemical Substances at Samara State Technical University, etc.

Our Research and Development Department is led by Nail G. Ibragimov, Dr.-Ing, Laureate of the State Prize, Chemist Emeritus of the Russian Federation, and Department Head of FGUP MP R&D Center focusing on selection of compositions for solid fuel powders. Vladimir V. Laptev, Dr.-Ing., General Director of OJSC NPF Geophysics, Honored Worker of Science and Technology of the Republic of Belarus, is our consultant for PTA impact study in relation to solid fuel generators.

SGK Region authored over 150 research papers including 30 patents, as well as publications in Russia and worldwide on related topics such as missilery and ammunition disposal.

Quality

Contacts

Russian Federation, 443016, Samara city, Cheremshanskaya street, 93a, 8 appt.

phone (846) 951-96-57, 247-81-29

e-mail: info@sgk-region.ru